Mechanical Finishers, Inc. has provided mass finishing services to the Ohio Valley’s metal deburring, metal passivating, metal parts cleaning, zinc plating and metal finishing services cincinnati needs since 1992 under the MFI banner. We have rapidly become one of the largest finishing facilities in Ohio.

ESTABLISHED SINCE 1985

Providing Mass Finishing and Mechanical Finishing Services

Get In Touch

Mechanical Finishing Services : Benefits of Mass Finishing and Mechanical Finishing Services

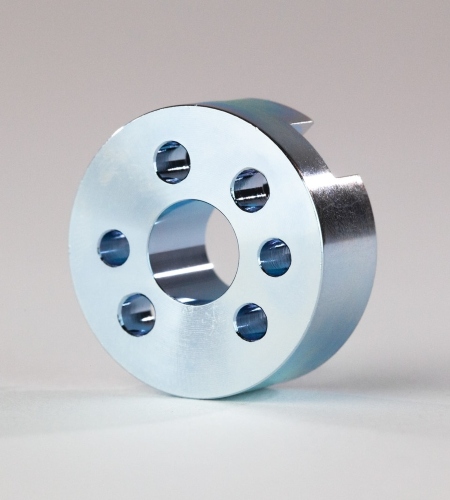

Mechanical finishing services Ohio refer to a variety of processes used to alter the surface texture, appearance, and/or performance of a material or product. These processes may involve the use of mechanical abrasion, polishing, or other techniques to achieve the desired result. Some examples of mechanical finishing services include sandblasting, buffing, grinding, lapping, and honing. These services can be used in a wide range of industries, from automotive and aerospace to consumer goods and construction. The specific method used will depend on the desired outcome, the material being worked on, and other factors such as the production process and cost considerations.

Benefits of Mass Finishing and Mechanical Finishing Services

Mass finishing and mechanical finishing services offer a wide range of benefits to manufacturers and other businesses that rely on these processes to improve the quality of their products. Some of the key benefits include:

Improved surface quality: Mass finishing and mechanical finishing can be used to achieve a range of surface finishes, from mirror-like polishing to roughening or texturing. These finishes can improve the aesthetics and functionality of a product, as well as enhance its durability and resistance to wear and corrosion.

Increased efficiency: Mass finishing techniques can often process a large number of parts or components at once, reducing the time and cost required for finishing. Additionally, mechanical finishing services can often automate and optimize the finishing process, reducing labor costs and improving consistency and quality.

Customization and flexibility: Mass finishing and mechanical finishing services offer a high degree of customization and flexibility, allowing manufacturers to achieve the exact finish or performance characteristics they require. Different media, compounds, and equipment can be used to tailor the process to specific materials, geometries, and surface requirements.

Environmental benefits: Many mass finishing and mechanical finishing processes use environmentally-friendly media and compounds, reducing the amount of waste and harmful chemicals produced. Additionally, these processes can often be designed to minimize energy consumption and other resource use, improving the sustainability of the manufacturing process.

Improved safety: Mass finishing and mechanical finishing services can help to reduce the risk of injury to workers by automating or mechanizing potentially hazardous finishing tasks. Additionally, they can often be designed to reduce exposure to harmful dust, fumes, and other hazards associated with traditional finishing techniques.

Overall, mass finishing and mechanical finishing services offer a wide range of benefits that can help manufacturers to improve the quality, efficiency, and sustainability of their production processes.

WHAT WE DO

Our Services

OVERVIEW ON OUR CAREER

Quick Facts

Years of Experience

Different Services

Satisfied Clients

FREE CONSULTATION

Receive your quote today

Fill out the application form and our specialist will contact you for a consultation.