Metal Finishing Ohio: Mechanical Finishers, Inc Services

Ohio’s Top Metal Finishing Provider: Mechanical Finishers, Inc

Key Highlights

- They have over thirty years of experience in metal finishing.

- They offer many metal finishing services, like deburring, blasting, and passivation.

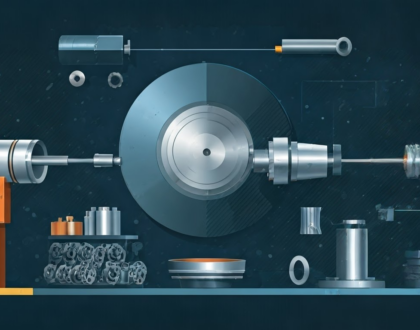

- They use advanced technology and equipment to get great results.

- They are dedicated to giving special solutions for each project.

- They are known for quick service, fair prices, and excellent customer support.

Introduction

Mechanical Finishers Inc. is a leader in mechanical finishing services and metal finishing services in the Ohio Valley. We work hard to ensure quality and keep our customers happy. This focus has helped us build a strong reputation for great results. If you need surface finishing, deburring, or any other related service, Mechanical Finishers Inc. has the skill and experience to meet your needs.

Why Choose Mechanical Finishers, Inc. for Your Metal Finishing Needs

We know that picking the right metal finishing company is very important for your projects. At Mechanical Finishers, Inc., we have a special mix of experience, skills, and a strong focus on quality that makes us different. Our team is here to give you personal solutions to fit your needs. We promise to pay attention to every detail for the best results.

Our modern facility has top-notch machinery. This helps us work on projects of any size, both quickly and accurately, including scrap steel projects. We also care about the environment. We use eco-friendly practices in our work to reduce our impact while delivering great metal finishing services.

A History of Excellence in the Ohio Valley Since 1992

Founded in 1992, Mechanical Finishers Inc. has a strong history in Ohio Valley’s metal finishing. For more than thirty years, we have worked hard to provide our clients with top-notch metal finishing, deburring, and parts cleaning services that ensure a high-quality finish. Our focus on great craftsmanship and happy customers has made us a trusted partner to many businesses.

Over the years, Mechanical Finishers Inc. has invested in modern equipment and technology. This helps our clients get the best and most efficient metal finishing solutions. By staying current with industry trends, we tackle tough projects confidently and often exceed what our clients expect.

We are proud of our history of excellence. We remain dedicated to keeping the highest standards in our work. Our love for metal finishing, along with our strong commitment to customer happiness, makes Mechanical Finishers Inc. the best choice for all your metal finishing needs.

Comprehensive Range of Services: Finishing, Deburring, and More

At Mechanical Finishers, Inc., we provide many metal finishing services for your parts cleaning needs, including surface treatment options. We are a leading job shop that focuses on surface finishing, metal deburring, and parts cleaning. Our services are perfect for many industries and uses.

Here are some of the services we offer:

- Vibratory Finishing: This is great for cleaning, deburring, and improving the surface of many metal parts.

- Tumble Blasting: This works well for cleaning, de-scaling, and preparing the surfaces of different metal pieces.

- Centrifugal Disc Finishing: This gives a high-energy and exact deburring solution for detailed parts and delicate materials.

- Burnishing: This improves the surface finish of metal parts, making them smooth and shiny.

No matter how tricky your metal finishing needs might be, we have the skills, equipment, and dedication to quality to provide great results. When you choose Mechanical Finishers, Inc., you can be sure that your parts will get the careful and expert treatment they need.

Our Metal Finishing Processes Explained

Metal finishing includes different methods that aim to improve the surface of metal parts. These methods can change how rough the surface feels, how well it resists corrosion, or how it looks.

Our team has skilled technicians who know a lot about many metal finishing techniques. This includes deburring, grinding, polishing, and more. We will help you choose the best methods to get the results you want for your project needs.

The Importance of Metal Deburring

Metal deburring is very important in making sure we produce high-quality parts that work well and are safe. Deburring gets rid of sharp edges, burrs, and other problems that can happen during making parts. If we don’t fix these issues, we can face several problems, such as:

- Lower performance: Burrs can mess up how parts fit and work, leading to quick wear or even breaking.

- Safety risks: Sharp edges and burrs can cause injuries when handling, putting together, or using parts.

- Less attractive look: Burrs and surface problems can ruin the appearance of finished products.

By using the right metal deburring methods, Mechanical Finishers, Inc. makes sure your parts are free from these issues. This improves their quality, dependability, and looks.

Advanced Metal Passivating Techniques

Metal passivating is a key step that makes metal parts, especially stainless steel, resistant to corrosion. This process puts a protective oxide layer on the metal’s surface using a chemical treatment. This helps prevent rust and other types of damage.

At Mechanical Finishers, Inc., we use advanced methods for metal passivating to achieve great results. Our process includes placing parts in special acidic solutions to remove free iron and other dirt from the surface. This creates bubbles that pop, leading to the implosions of bubbles that take away impurities stuck in the material. As a result, we are left with a clean and passivated surface. We have strict quality control measures in place. This guarantees that the passivation layer meets industry standards, ensuring your metal parts are protected for a long time.

Conclusion

In conclusion, Mechanical Finishers, Inc. is the best choice for metal finishing in Ohio. They have a strong history of providing excellent service since 1992. They offer many services such as finishing and deburring to meet different metal finishing needs. They pay great attention to quality and use advanced methods, like metal passivating, to give the best results for each project. If you need a reliable partner for metal finishing in the Ohio Valley, Mechanical Finishers, Inc. is the trusted option for outstanding results and happy customers. Contact us today to see our special skills in metal finishing solutions.

Frequently Asked Questions

What metal finishing services does Mechanical Finishers, Inc. offer?

Mechanical Finishers, Inc. offers many surface finishing services, including vibratory finishing as part of the manufacturing process, tumble blasting, centrifugal disc finishing, and burnishing. We adjust our services to meet the specific needs of each project.

How does Mechanical Finishers, Inc. ensure quality in their finishing processes?

We are a leading job shop with an art facility. Our facility has technology that gives our team live data. This helps us watch every step of the finishing process. We can quickly make any corrections to ensure a high-quality finish.

Can Mechanical Finishers, Inc. handle large-scale metal finishing projects?

Yes, our facility can manage big projects. We are one of the largest finishing facilities in Ohio. We have the right machinery and know-how to provide the durability and type of finish you need. Plus, we can get it done in a very short amount of time.

Recent Posts

Top Metal Finishing Company Ohio: Mechanical Finishers, Inc.

February 11, 2025

How Zinc Plating Enhances Corrosion Resistance

March 16, 2024