Top Metal Finishing Company Ohio: Mechanical Finishers, Inc.

Ohio’s Best Metal Finishing Company | Mechanical Finishers, Inc.

Key Highlights

- Mechanical Finishers, Inc. is a leading provider of metal finishing services in Ohio.

- The company offers a wide range of services, including deburring, plating, and powder coating.

- Mechanical Finishers, Inc. is committed to providing its customers with the highest quality services and products.

- The company has a team of experienced professionals who are dedicated to meeting the needs of its customers.

- Mechanical Finishers, Inc. is an ISO 9001:2015 certified company.

Introduction

For many years, Mechanical Finishers, Inc. has been a trusted name in metal finishing. We consistently deliver great results and keep our customers happy. With our years of experience, our ISO-certified facility has a wide range of services. These services meet the different needs of our valued clients. Our strong commitment to quality and precision makes us a top choice for businesses looking for reliable and effective metal finishing solutions.

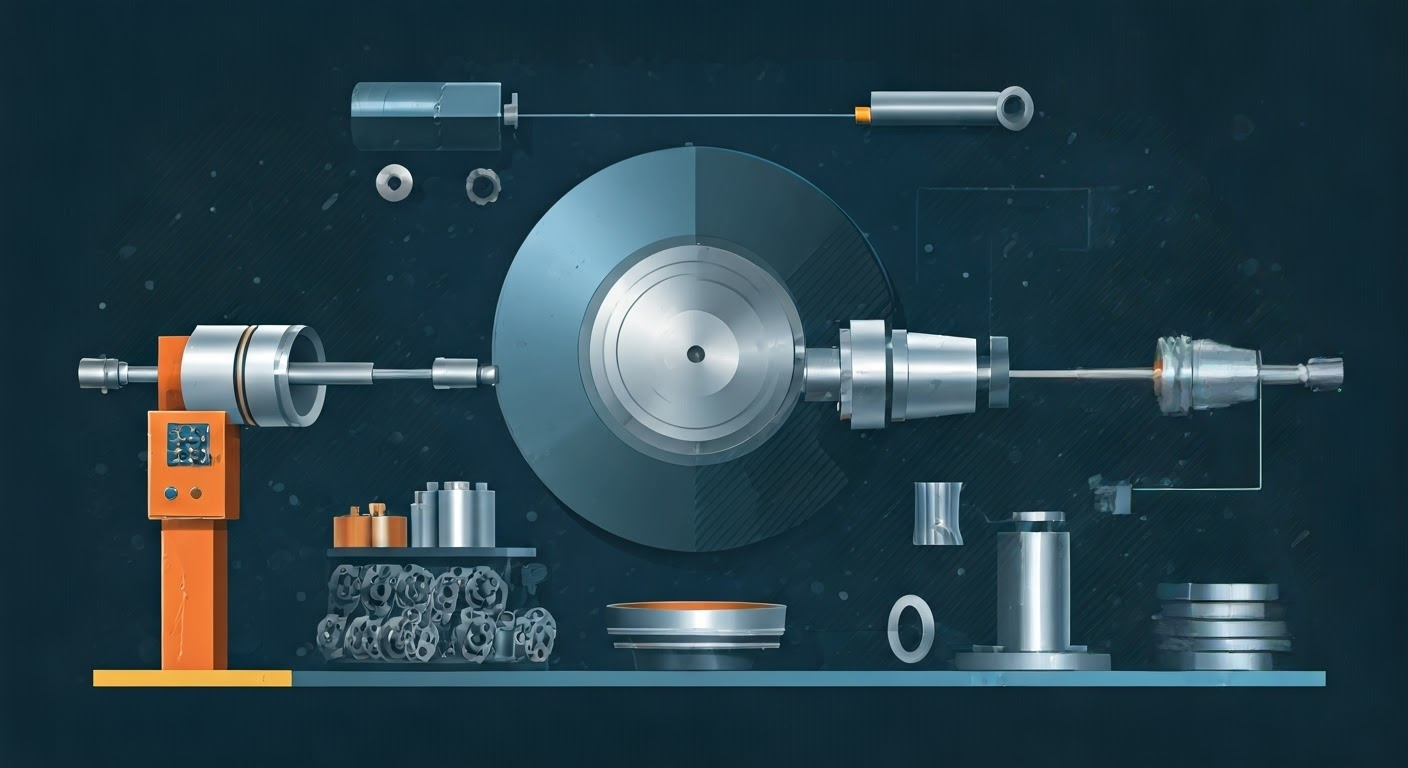

Understanding Metal Finishing and Deburring Services

Metal finishing is about changing a metal part’s surface. This is done to improve its look, prevent rust, or make it last longer. There are many ways to finish metal, like plating, coating, and deburring. Deburring is when we remove sharp edges and other flaws from the surface.

Metal finishing is about changing a metal part’s surface. This is done to improve its look, prevent rust, or make it last longer. There are many ways to finish metal, like plating, coating, and deburring. Deburring is when we remove sharp edges and other flaws from the surface.

This step is very important. It helps the part work well, stay safe, and look good. Mechanical Finishers, Inc. provides many metal finishing and deburring services. We tailor our services to fit each customer’s project needs. Whether you want to make a product stronger or better looking, we are here to help with all your metal finishing needs.

The Importance of Quality Metal Finishing

Metal finishing is very important in many industries. This includes aerospace, automotive, medical, and manufacturing. The highest quality finish can really affect a product’s performance, how long it lasts, and its overall value. For example, in the aerospace industry, where precision and reliability matter a lot, good metal finishing helps parts resist tough conditions and stay strong.

Metal finishing is very important in many industries. This includes aerospace, automotive, medical, and manufacturing. The highest quality finish can really affect a product’s performance, how long it lasts, and its overall value. For example, in the aerospace industry, where precision and reliability matter a lot, good metal finishing helps parts resist tough conditions and stay strong.

A proper finish can also improve a product’s resistance to corrosion. This is vital in fields where parts face moisture, chemicals, or extreme temperatures. By stopping rust and other kinds of corrosion, metal finishing helps extend a product’s life and lowers the chances of needing expensive replacements.

Choosing quality metal finishing services from a trusted company like Mechanical Finishers, Inc. is a smart choice. This decision can benefit your products and also help your business.

Deburring Techniques for Precision and Efficiency

Deburring is an important part of finishing metal. There are different ways to deburr, each one is best for certain materials and results. Choosing the right method depends on factors like the size and shape of the part, what it is made of, and how many pieces you have to process. Here are some common deburring methods:

- Vibratory Finishing: This method uses a vibrating bowl filled with rough material. It helps to smooth out rough edges and remove burrs.

- Brush Deburring: This is great for delicate or complex parts. It uses rotating brushes with rough fibers to deburr specific areas accurately.

- Electrochemical Deburring: This method uses a special process to dissolve burrs. It is good for complex parts with hard-to-reach spots.

Mechanical Finishers, Inc. uses advanced equipment and knows these deburring methods well. They work hard to give results that meet your specific needs. Whether you need a smooth finish on zinc-plated parts or strict standards for aerospace components, they ensure your products meet the highest industry standards.

Their skilled team focuses on improving every step of the deburring process. They make sure it’s efficient while keeping quality strong. This careful work ensures your parts are precise and perform well, giving you confidence in the results.

Conclusion

Mechanical Finishers, Inc. is Ohio’s top metal finishing company. They focus on quality and precision in metal finishing and deburring services. Good metal finishing is very important, especially in industries that need the best results. Mechanical Finishers, Inc. uses advanced deburring methods to ensure that every project is efficient and accurate. If you want the best metal finishing services for your industry, contact Mechanical Finishers, Inc. Their skill and dedication will raise the quality of your products significantly.

Frequently Asked Questions

What sets Mechanical Finishers, Inc. apart in metal finishing?

Mechanical Finishers, Inc. has many years of experience in offering great metal finishing services. We specialize in chrome plating and electropolishing. We have several certifications, and we always aim to keep the highest industry standards.

What industries can benefit from the metal finishing services provided by Mechanical Finishers, Inc.?

Our ISO-certified facility serves many industries, such as aerospace and automotive. We focus on precision zinc coating and other metal finishing solutions. These services are useful for a variety of applications.

How can I request a quote or consultation with Mechanical Finishers, Inc.?

At Mechanical Finishers, Inc., we care about your satisfaction! If you want to ask for a quote or talk with us about your needs, please reach out. We will go over your specifications and help you step of the way to achieve excellence in metal finishing.

Recommended Posts

How Zinc Plating Enhances Corrosion Resistance

March 16, 2024

Primary Components of Mass Finishing

January 19, 2023